|

CONTINUING EDUCATION: CONTINUING EDUCATION:

The two-day program was preregistered with the Am,erican Institute of Architects Continuing Education System for 12 Continuing Education HSW LU’s.

CONFERENCE CO-SPONSORS:

NORTHEAST CHAPTER

CORPORATE SPONSORS:

STONE & LIME IMPORTS, INC.

STRUCTURES NORTH CONSULTING ENGINEERS

JOSEPH GNAZZO CO.

BERMUDA MARITIME MUSEUM

PRESENTATION ABSTRACTS & SPEAKER BIO’s

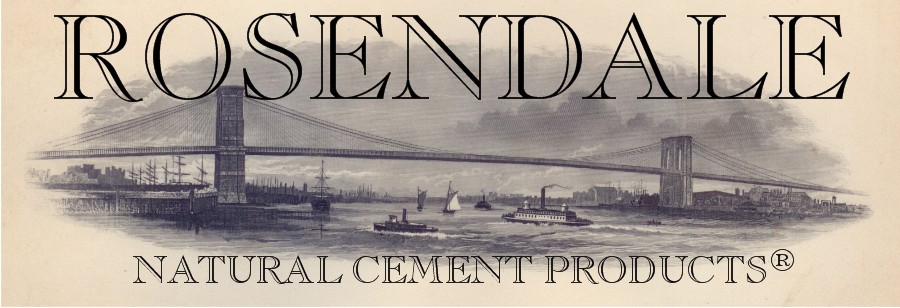

1. Dietrich Werner, The History of the Rosendale Natural Cement Region

ABSTRACT: More than 70 billion pounds of natural cement were produced from 1818 to 1915. It is estimated that half of that total was mined and processed in Rosendale, New York. The natural cement industry not only had profound effects on this Hudson Valley community, but also influenced the development of New York City as America’s largest city. This presentation will reflect on the history of the Rosendale Cement region and its effects on American History. ABSTRACT: More than 70 billion pounds of natural cement were produced from 1818 to 1915. It is estimated that half of that total was mined and processed in Rosendale, New York. The natural cement industry not only had profound effects on this Hudson Valley community, but also influenced the development of New York City as America’s largest city. This presentation will reflect on the history of the Rosendale Cement region and its effects on American History.

BIO: Dietrich Werner is President of the Century House Historical Society. The Century House Historical Society is a not-for-profit educational organization dedicated to the industrial history of the Rosendale natural cement region. The Society is located at the Snyder Estate in New York's historic Hudson Valley.The Snyder Estate Natural Cement Historic District is listed on the National Register of Historic Places.The Society is chartered by the New York State Education Department.

2. Kurtis Burmeister, Geology and Mining of Rosendale Natural Cement Rock

ABSTRACT: The geological processes that led to the formation of argillaceous limestone (“natural cement rock”) are reviewed, and the geology of the Rosendale cement region is placed in context with other natural cement formations that were mined in North America in the 19th Century. The nature of the various strata of natural cement rock is discussed and the mining methods used to extract this valuable resource are illustrated. The vast remaining natural cement rock resources in Rosendale are also considered. ABSTRACT: The geological processes that led to the formation of argillaceous limestone (“natural cement rock”) are reviewed, and the geology of the Rosendale cement region is placed in context with other natural cement formations that were mined in North America in the 19th Century. The nature of the various strata of natural cement rock is discussed and the mining methods used to extract this valuable resource are illustrated. The vast remaining natural cement rock resources in Rosendale are also considered.

BIO: Kurtis Burmeister is an Associate Professor of Geology at California State University at Bakersfield. He has spent a great deal of time in the Rosendale cement region, visiting old mine sites, and studying and cataloguing the region’s geology and mining methods.

3. John Walsh, Petrography: Identification of Natural Cement in Existing Buildings

ABSTRACT: Petrographic analysis is a microscopy method that provides a unique and revealing view of inorganic materials. Hydraulic cements rarely react completely and telltale residuals are detected when the forensic petrographer is properly trained in their identification. Combined with accurate chemical analysis, the petrographic examination not only identifies the original components but often allows for a quantitative assessment of material proportions and original binder chemistry. Such data is crucial for the proper conservation and rehabilitation of historic structures. Portland cement, hydraulic lime, and natural cement in any combination may be present in 19th century and early twentieth century masonry construction. A comprehensive petrographic examination serves as the basis for the successful creation and implementation of an historically accurate project specification. This presentation provides insight into how various contemporary and historic binders are properly distinguished and their mortars reverse engineered. While technical data will be offered, the goal of the presentation is to provide the architect or specifier with a general understanding of the methods employed by the petrographer and to demystify the often complicated petrographic report. Case studies will be discussed with an emphasis on the pitfalls of an inaccurate petrographic analysis. Finally, the petrographic identification of the often misidentified Rosendale cement will be addressed with some discussion of current research into its various incarnations in historic structures.

BIO: John Walsh is a former NSF Graduate Research Fellow with a Masters Degree in Structural Geology from Columbia University. His early research focused on carbonate microstructure in natural fault zones; an experience ultimately leading to a career studying the microstructure of cementitious materials. He is now a Geologist and Senior Petrographer at Testwell Laboratories in Ossining, NY where he specializes in the reverse engineering of existing materials and investigating failures related to material deficiencies and environmental exposure. He is currently serving as Secretary of the Society of Concrete Petrographers and is active in various ASTM subcommittees. As a native fifth generation New Yorker, the investigation of construction materials and practices in historic NYC structures was a natural progression in John's career. He is currently researching the petrography and chemistry of the Rosendale cement that has played an important role in many of New York's landmarks and early infrastructure.

4. Mike Ryan, Historical Use of Natural Cement by the US Army Corps of Engineers

ABSTRACT: Following its inception in 1802, the U.S. Army Corps of Engineers became an innovator in the design, construction, and evolution of large masonry structures. Early in its history the Corps of Engineers specialized in the development of coastal defenses. During the aftermath of the War of 1812—a conflict that illustrated the need for additional coastal defenses—the so-called Third System fortifications were begun. Over the next five decades a chain of more than fifty powerful coastal forts evolved under the leadership of Generals Simon Bernard and Joseph Totten. Natural cement was a key component used by the Corps of Engineers in the construction of many of these fortresses. Such impressive works as Fort Adams (Narragansett Bay), Fort Monroe (Chesapeake Bay), and Fort Jefferson (Dry Tortugas) exemplify the skill of their designers, and the quality of their construction materials. ABSTRACT: Following its inception in 1802, the U.S. Army Corps of Engineers became an innovator in the design, construction, and evolution of large masonry structures. Early in its history the Corps of Engineers specialized in the development of coastal defenses. During the aftermath of the War of 1812—a conflict that illustrated the need for additional coastal defenses—the so-called Third System fortifications were begun. Over the next five decades a chain of more than fifty powerful coastal forts evolved under the leadership of Generals Simon Bernard and Joseph Totten. Natural cement was a key component used by the Corps of Engineers in the construction of many of these fortresses. Such impressive works as Fort Adams (Narragansett Bay), Fort Monroe (Chesapeake Bay), and Fort Jefferson (Dry Tortugas) exemplify the skill of their designers, and the quality of their construction materials.

BIO: Mike Ryan is employed by the National Park Service and is the lead interpreter at Fort Jefferson, Dry Tortugas National Park, off the Florida coast. His degrees include a MS and a MA in American military history. During his National Park Service career he was worked at numerous historic sites, including six Third System forts. He has visited and studied virtually all of the 19th-century coastal fortifications, and is considered a leading expert on their history.

5. Josh Kivela, Early Strength of Various Masonry Binders

ABSTRACT: Over the past several years, hydraulic lime and other natural cement mortars have been rediscovered by the conservation/restoration community as potential substitutes for cement/lime based formulations. Natural cement mortars show great potential in restoration by having some of the advantageous properties of portland cement (adequate strength and good workability) as well as other properties that are inherent to most natural cements (small cyclic volume changes, good water vapor transmission rates, etc.). This presentation is part of a larger research project that aims to quantify the early strength development, bond strength, and water vapor permeance characteristics of hydraulic lime and natural cement mortars. Portland cement based mortars are also tested for comparison. The vapor drive characteristics of several historic load-bearing masonry wall systems are modeled using WUFI (a German computer program used to model heat and moisture flow through walls). Different mortars and masonry cladding systems are used and the results compared. A further aim of the research is to investigate the use of hydraulic lime and natural cement mortars for modern, short-duration restoration and construction projects. ABSTRACT: Over the past several years, hydraulic lime and other natural cement mortars have been rediscovered by the conservation/restoration community as potential substitutes for cement/lime based formulations. Natural cement mortars show great potential in restoration by having some of the advantageous properties of portland cement (adequate strength and good workability) as well as other properties that are inherent to most natural cements (small cyclic volume changes, good water vapor transmission rates, etc.). This presentation is part of a larger research project that aims to quantify the early strength development, bond strength, and water vapor permeance characteristics of hydraulic lime and natural cement mortars. Portland cement based mortars are also tested for comparison. The vapor drive characteristics of several historic load-bearing masonry wall systems are modeled using WUFI (a German computer program used to model heat and moisture flow through walls). Different mortars and masonry cladding systems are used and the results compared. A further aim of the research is to investigate the use of hydraulic lime and natural cement mortars for modern, short-duration restoration and construction projects.

BIO: Mr. Kivela is an Engineer/Lab Technician at Simpson Gumpertz & Heger (SGH) in Waltham, MA and a graduate student at Northeastern University in Boston, MA. He has over five years of experience in investigation, evaluation, design, restoration, and construction phase monitoring and administration of historic and modern buildings. He will receive his Masters Degree in Materials Science and Engineering from Northeastern University in 2005. SGH is an ENR 500 consulting engineering firm that designs, investigates, and retrofits buildings and structures of all types. Their thirteen services focus in the areas of Building Engineering, Infrastructure and Special Structures, and Construction Engineering.Mr. Kivela is an ACI Certified Concrete Technician at the AASHTO Accredited SGH Laboratory. He conducts mechanical and chemical tests on concrete, metals, brick and stone masonry, glass, plastics, and composite materials following ASTM and project specific test procedures. He has worked extensively for Yale University during the construction of a $10,000,000 biomedical facility and stairway and fašade renovations of several circa 1920’s masonry buildings. He is also a member of the “Green Team” special interest group that promotes energy conservation and green building practices.Mr. Kivela is researching and testing natural and portland cement based mortars as part of his Masters Thesis. His work is partially sponsored and supported by Northeastern University, SGH, and several local and international cement producers.

6. KEYNOTE PRESENTATION: Eric DeLony, Natural Cement Bridges and Current Issues in Historic Bridge Preservation

ABSTRACT: Natural Cement was commonly used in the construction of 19th Century bridges and industrial structures, many of which survive today. This presentation looks back at the history of natural cement use in 19th century bridge construction and takes a look at some examples of bridges that remain in service, carrying traffic, others that have been preserved for recreational uses, and others that are endangered. The preservation priorities, issues and challenges in Historic Bridge Preservation will be discussed.

BIO: Eric DeLony devoted 32 years to the Historic American Engineering Record, an information and image database housed at the Library of Congress, serving for many years as its Chief, during his career at the National Park Service. He is an Architect by training, has been a lecturer and teacher, and is considered one of the nation’s foremeost experts on historic bridges and industrial structures. He is currently a consultant and activist, working for the preservation of historic bridges.

7. Mary Catherine Martin, Restoration Architecture: Current Use of Rosendale Cement in Historic Restoration

ABSTRACT: The use of authentic, traditional materials in the restoration of historic buildings and structures is an important element in the preservation of these sites’ historic integrity. This paper begins with the author’s experiences in researching the historical use of natural cement in the original construction of Fort Adams in Newport, RI and at Fort Jefferson, Florida. This knowledge was then applied to a demonstration project at Fort Jefferson in 2004, during which the feasibility of restoration-in-kind using natural cement was proven. The experience gained during the demonstration phase became the basis on which specifications for the current construction phase were developed.

BIO: Mary Catherine Martin, AIA, is a Senior Architect with the firm of Lord Aeck Sargent in Atlanta, GA.

8. John Wathne, Engineering: Structural Performance of Natural Cement

ABSTRACT: With the revival of Rosendale Natural Cement production, it can be expected that this material will help bridge the gap in sympathetic restoration technology between old-world lime based construction and modern-world Portland cement based construction. When discovered, the properties of Natural Cement allowed for more rapid construction and enhanced durability, properties which we still seek today.Much research was done in the latter half of the 19th Century on Natural Cement, having been published by the US War Department and in other sources. Much work is currently being done to establish, test and standardize physical structural properties for construction binders of all types and ages. With the revival of Rosendale Cement, the need has arisen to look anew upon this historic material and to put it into the context of today's more highly defined standards. ABSTRACT: With the revival of Rosendale Natural Cement production, it can be expected that this material will help bridge the gap in sympathetic restoration technology between old-world lime based construction and modern-world Portland cement based construction. When discovered, the properties of Natural Cement allowed for more rapid construction and enhanced durability, properties which we still seek today.Much research was done in the latter half of the 19th Century on Natural Cement, having been published by the US War Department and in other sources. Much work is currently being done to establish, test and standardize physical structural properties for construction binders of all types and ages. With the revival of Rosendale Cement, the need has arisen to look anew upon this historic material and to put it into the context of today's more highly defined standards.

This lecture will attempt to (1) establish an understanding of Natural Cement’s known physical structural properties, (2) identify the physical structural properties that still need to be determined, and (3) show where Natural Cement is in comparison with other structural binders, based upon the information that has been gathered to date.

BIO: John Wathne, PE, is a Structural Engineer, specializing in the evaluation, stabilization and restoration of historic structures, with an emphasis on masonry and timber structures. A graduate of Lehigh University, he is the founder and president of Structures North Consulting Engineers, Inc., which is involved in more than 80 to 100 historic preservation, restoration and adaptive re-use projects per year, throughout the New England region. He has published articles on the subjects of thermal prestressing of existing steel structures under load (Modern Steel Construction), and the restoration of load bearing terra cotta structures (Masonry Construction). He also has hands-on construction experience as a timber framer as well as in microscopic identification of wood species and visual grading of historic timbers.

Mr. Wathne has completed numerous publicly and privately funded restoration projects of historic load-bearing and non-load bearing masonry structures that include churches, theaters, municipal buildings, monuments and subterranean mound tombs, towers of as much as 170 feet in height, and the stone liner stabilization in the oldest railway tunnel in the Americas. He heads the “Properties” task group for ASTM Committee C12.3.3, which is charged with writing a new standard specification for mortar for use in historic structures.

9. John Lambert, A Clearer Perspective on the Evolution of Early American Mortars

ABSTRACT: This paper presents a wealth of new research and information regarding the evolution of American unit masonry mortars during the late 1800’s and early 1900’s. In recent years, a significant amount of attention has been paid to the history of Portland Cement and lime putty binders, and their effects on our early American unit masonry mortars. This has been done at the expense of overlooking the use of hydraulic limes, natural cements, and dry hydrate binders and how their advent significantly changed early American mortars in the late 1800’s and early 1900’s. This paper more fully exposes the development, distribution and extensive use of these unique mortar binders, and explains why this new knowledge is important for architects, contractors, specifiers, building owners, engineers and craft persons today. The paper is based on excerpts from numerous writings obtained from period books and manuscripts of the time. The appropriate information has been carefully selected, organized and chronologically arranged for easy understanding and assimilation by the participant. The significance of this paper’s content to the conference and the intended audience is that it is important that today’s preservation professionals combine both modern day investigative technologies as well as historic factual information in order to determine the most appropriate repair mortar for our historic masonry buildings and monuments. This marriage will ensure the most enduring solution for these structures, and will assist in perpetuating their survival into the future. ABSTRACT: This paper presents a wealth of new research and information regarding the evolution of American unit masonry mortars during the late 1800’s and early 1900’s. In recent years, a significant amount of attention has been paid to the history of Portland Cement and lime putty binders, and their effects on our early American unit masonry mortars. This has been done at the expense of overlooking the use of hydraulic limes, natural cements, and dry hydrate binders and how their advent significantly changed early American mortars in the late 1800’s and early 1900’s. This paper more fully exposes the development, distribution and extensive use of these unique mortar binders, and explains why this new knowledge is important for architects, contractors, specifiers, building owners, engineers and craft persons today. The paper is based on excerpts from numerous writings obtained from period books and manuscripts of the time. The appropriate information has been carefully selected, organized and chronologically arranged for easy understanding and assimilation by the participant. The significance of this paper’s content to the conference and the intended audience is that it is important that today’s preservation professionals combine both modern day investigative technologies as well as historic factual information in order to determine the most appropriate repair mortar for our historic masonry buildings and monuments. This marriage will ensure the most enduring solution for these structures, and will assist in perpetuating their survival into the future.

BIO: John Lambert is President and CEO of Abstract Masonry Restoration, a 19 year old historic masonry restoration contracting and consulting company located in both Boston, Massachusetts and Salt Lake City, Utah. He has provided the historic masonry consulting and/or contracting services for several of America’s most notable masonry buildings. John is actively involved in providing hands-on training to those interested in learning how to properly care for historic masonry structures. He is the instructor for the 3 to 4 day, hands-on workshops held at both The Campbell Center for Historic Preservation Studies in Mount Carroll, Illinois, as well as The Traditional Building Skills Institute at Snow College in Utah. Several of John’s students join him each year in traveling to England and Wales to further study historic masonry and work on historic masonry buildings abroad. In addition to serving on several historic preservation related boards, his preservation leadership includes serving as the past Chairman of the Board of The Traditional Building Skills Institute. He has traveled and trained in England, Scotland, Ireland, Wales and France. He also serves on ASTM Subcommittee C12.03.03, the task group charged with developing new standards for restoration mortars. John is a passionate collector of rare and historic books, art and documents written on masonry during the 1700’s to early 1900’s. As an avid student of these valuable resources, he has gained unique insight into the minds of the architects, engineers and craftsmen of the time.

10. Michael Edison, Formulating Rosendale Cement Mortars

ABSTRACT: This paper reviews the well-documented formulation practices from the 19th and 20th centuries, utilizing natural cement as the sole binder, primary binder, or as an additive in a wide variety of cement-based materials. These include masonry mortars, renders and stucco’s, limewashes and early concretes. In most cases, restoration of these traditional materials will best be performed by duplicating the original formulations. ABSTRACT: This paper reviews the well-documented formulation practices from the 19th and 20th centuries, utilizing natural cement as the sole binder, primary binder, or as an additive in a wide variety of cement-based materials. These include masonry mortars, renders and stucco’s, limewashes and early concretes. In most cases, restoration of these traditional materials will best be performed by duplicating the original formulations.

Beyond the practices of earlier times, there are also potential applications for natural cement in masonry grouting, composite repair and precasting, three non-traditional applications in which there is benefit to be gained from the unique performance characteristics and general compatibility of natural cement with masonry substrates. Five decades of developments in cement additives technology have never been applied to natural cements. This paper begins to explore the potential for use of natural cement in combination with modern additives.

BIO: Michael Edison, chemical engineer, is President and Founder of Edison Coatings, Inc. in Plainville, CT. His engineering career spans more than 30 years, during which he has worked in the development and formulation of custom mortars and coatings for stone, masonry and concrete. Edison Coatings is currently processing Rosendale natural cement rock into natural cements, and is compounding these materials into a variety of traditional masonry mortars, renders and concrete materials. Edison has authored a number of articles on repair and coatings technology and has been a frequent lecturer at restoration industry events. He has had technical articles published by APT Journal of Preservation Technology, ICRI Concrete Repair Bulletin, Journal of ASTM International and SWRI Applicator, among others. He is a past chairman of the Central New York Section of the American Institue of Chemical Engineers, a Past President of the Connecticut Chapter of the International Concrete Repair Institute and a current Director on the Board of the Association for Preservation Technology Northeast Chapter. He chairs ASTM Task Group C1.10.04 on Natural Cement.

11. Ken Uracius, The Natural Cement Revival

ABSTRACT: Four years ago, Ken Uracius was a masonry restoration specialist working as Director of Restoration for a masonry restoration contractor in New England. As the European Lime Revival reached the United States, he became a student of traditional lime, lime putty and hydraulic lime technology and an active advocate of the use of historically accurate materials in restoration work. But the more he learned, the more he came to realize that American buildings were very different in their construction, thus beginning his quest for the forgotten truth. The history and technology of natural cement use in the United States that he rediscovered led to the recent introduction of authentic Rosendale natural cement products for use in restoration.. In recounting his quest, Ken connects the dots between the technology, the people and the places where natural cement was used. Material demonstrations are used to illustrate key concepts. ABSTRACT: Four years ago, Ken Uracius was a masonry restoration specialist working as Director of Restoration for a masonry restoration contractor in New England. As the European Lime Revival reached the United States, he became a student of traditional lime, lime putty and hydraulic lime technology and an active advocate of the use of historically accurate materials in restoration work. But the more he learned, the more he came to realize that American buildings were very different in their construction, thus beginning his quest for the forgotten truth. The history and technology of natural cement use in the United States that he rediscovered led to the recent introduction of authentic Rosendale natural cement products for use in restoration.. In recounting his quest, Ken connects the dots between the technology, the people and the places where natural cement was used. Material demonstrations are used to illustrate key concepts.

BIO: Ken Uracius has been working around masonry for all of his life, and has 20 years of experience in directing major masonry construction and restoration projects. He is currently with Stone and Lime Imports, a firm dedicated to mining, promotion, distribution and technical support and training for traditional masonry materials.

Return to Rosendale Cement Home Page

BACK UP TO:

Introduction

Program & Schedule

Continuing Education - AIA HSW LU’s

Lodging & Hotel Reservation Form

Transportation

Conference Fees

Conference Registration Form

Speakers, Abstracts & Bios

Conference Co-Sponsors

|

ABSTRACT: The geological processes that led to the formation of argillaceous limestone (“natural cement rock”) are reviewed, and the geology of the Rosendale cement region is placed in context with other natural cement formations that were mined in North America in the 19th Century. The nature of the various strata of natural cement rock is discussed and the mining methods used to extract this valuable resource are illustrated. The vast remaining natural cement rock resources in Rosendale are also considered.

ABSTRACT: The geological processes that led to the formation of argillaceous limestone (“natural cement rock”) are reviewed, and the geology of the Rosendale cement region is placed in context with other natural cement formations that were mined in North America in the 19th Century. The nature of the various strata of natural cement rock is discussed and the mining methods used to extract this valuable resource are illustrated. The vast remaining natural cement rock resources in Rosendale are also considered.

ABSTRACT: This paper reviews the well-documented formulation practices from the 19th and 20th centuries, utilizing natural cement as the sole binder, primary binder, or as an additive in a wide variety of cement-based materials. These include masonry mortars, renders and stucco’s, limewashes and early concretes. In most cases, restoration of these traditional materials will best be performed by duplicating the original formulations.

ABSTRACT: This paper reviews the well-documented formulation practices from the 19th and 20th centuries, utilizing natural cement as the sole binder, primary binder, or as an additive in a wide variety of cement-based materials. These include masonry mortars, renders and stucco’s, limewashes and early concretes. In most cases, restoration of these traditional materials will best be performed by duplicating the original formulations.